When buying suit fabrics in bulk, I always prioritize quality, planning, and the reliability of my TR suiting fabric supplier. Skipping due diligence can lead to costly mistakes. For instance, ignoring a supplier’s legal standing or failing to check the consistency of polyester rayon spandex fabric might result in financial losses or operational setbacks. To avoid these pitfalls:

- Verify the supplier’s legal and operational status.

- Check for any ongoing disputes or obligations.

- Review contracts carefully to identify hidden risks.

- Confirm the accuracy of all supplier claims.

For TR suiting fabric or polyester rayon spandex blend fabric, these steps ensure a smooth buying process. Whether you’re a TR suiting fabric bulk buyer or sourcing polyester rayon spandex fabric, attention to detail safeguards your investment.

Key Takeaways

- Always check if the fabric supplier is trustworthy and legal. This helps avoid problems and ensures good service.

- Check fabric quality by looking at its material, feel, and color. Good fabrics make better products and keep customers happy.

- Plan bulk buying by knowing your customers and avoiding extra stock. This keeps inventory balanced and cuts down on waste.

Evaluating Fabric Quality

When buying suit fabrics, evaluating their quality is the cornerstone of making a sound investment. High-quality fabrics not only enhance the final garment’s appearance but also ensure durability and customer satisfaction. Here’s how I approach this critical step:

Understanding Fabric Composition

Fabric composition plays a vital role in determining the comfort, durability, and overall performance of a suit. I always start by checking the blend of fibers in the fabric. For instance, a polyester-rayon blend offers a balance of affordability and durability, while wool provides a luxurious feel and excellent breathability.

- Quality control standards, such as ISO 9001, help ensure that fabrics meet international requirements for safety and performance.

- Compliance with regulations like CPSC in the U.S. and REACH in Europe guarantees that the fabric composition is safe, especially for sensitive applications like children’s wear.

- Regular inspections during production help maintain consistent quality, while statistical sampling methods monitor fabric characteristics effectively.

Understanding the fabric’s composition allows me to assess whether it aligns with my needs and the expectations of my target market.

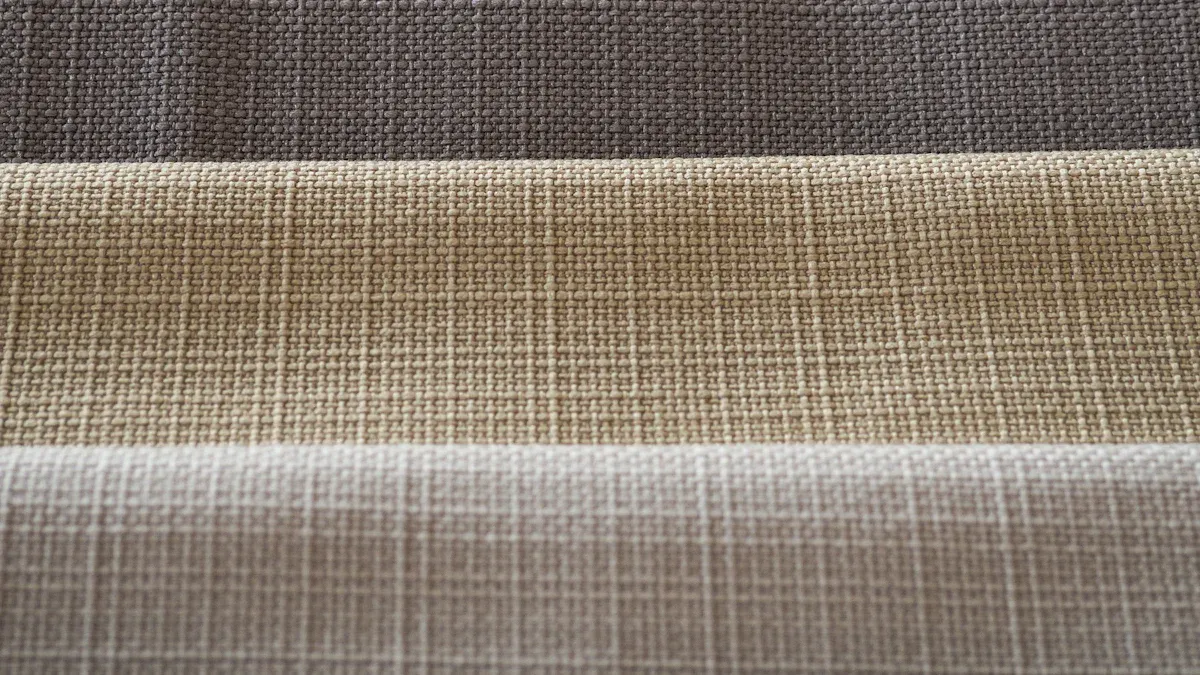

Checking Texture, Weight, and Drape

The texture, weight, and drape of a fabric significantly influence the fit and feel of a suit. I always evaluate these aspects to ensure the fabric meets my quality standards.

| Measurable Criteria | Description | Correlation Coefficient |

|---|---|---|

| Weight | Measured at 100 gf/cm | 0.94 |

| Bending Modulus | Related to drape behavior | 0.97 |

| Extensibility | Affects drape prediction | N/A |

| Drape Coefficient | Correlated with stiffness | N/A |

I also rely on expert assessments to validate the fabric’s drape and stiffness. High correlation between drape coefficients and subjective evaluations ensures that the fabric will perform well in the final garment. This step is crucial when buying suit fabrics in bulk, as it minimizes the risk of selecting unsuitable materials.

Assessing Color Fastness and Consistency

Color consistency is essential when purchasing fabrics in bulk. Variations in color can lead to mismatched garments, which is unacceptable in professional suiting. I use tools and techniques to ensure color accuracy:

| Method/Technique | Description |

|---|---|

| Spectrophotometers | Measure color to ensure matching and consistency. |

| Labdips | Provide dyed samples to match color standards. |

| Color Consistency | Maintain uniformity across dye lots and production batches. |

| Cost Efficiency | Prevent errors and material wastage by addressing discrepancies early. |

| Customer Satisfaction | Ensure the final product meets expectations regarding color. |

By using labdips and spectrophotometers, I can verify that the fabric’s color remains consistent across different rolls. This step not only saves costs but also ensures that the final suits meet the designer’s vision and customer expectations.

Inspecting for Defects or Irregularities

Before finalizing any bulk purchase, I thoroughly inspect the fabric for defects or irregularities. Common issues include uneven weaving, loose threads, or inconsistent dyeing. These flaws can compromise the quality of the final product. I recommend conducting regular inspections during production to catch these problems early.

- Inspections help identify issues like fabric tears, uneven textures, or color inconsistencies.

- Statistical sampling methods ensure that the majority of the fabric meets quality standards.

- Addressing defects early prevents costly rework and waste.

By paying close attention to these details, I can ensure that the fabrics I purchase in bulk are free from defects and ready for high-quality garment production.

Planning Your Suiting Fabric Bulk PurchaseIdentifying Your Needs and Target Market

When planning a bulk purchase of suiting fabrics, I always start by identifying my specific needs and understanding my target market. This step ensures that the fabrics I choose align with customer preferences and market demands. For instance, I analyze purchasing behaviors, occasions that drive demand, and how customers use the final products. This helps me tailor my selection to meet their expectations.

| Aspect | Description |

|---|---|

| Purchasing Behavior | Understanding how consumers make decisions, including information gathering and comparison of options. |

| Occasion Purchasing | Identifying specific events that drive purchases, such as holidays or personal milestones. |

| Customer Usage | Analyzing frequency of purchases to identify heavy, medium, and light users for targeted marketing. |

| Benefits of Segmentation | Understanding the motivations behind purchases to tailor marketing strategies effectively. |

By focusing on these aspects, I can make informed decisions about which fabrics to stock. This approach minimizes the risk of overstocking or selecting materials that don’t resonate with my audience.

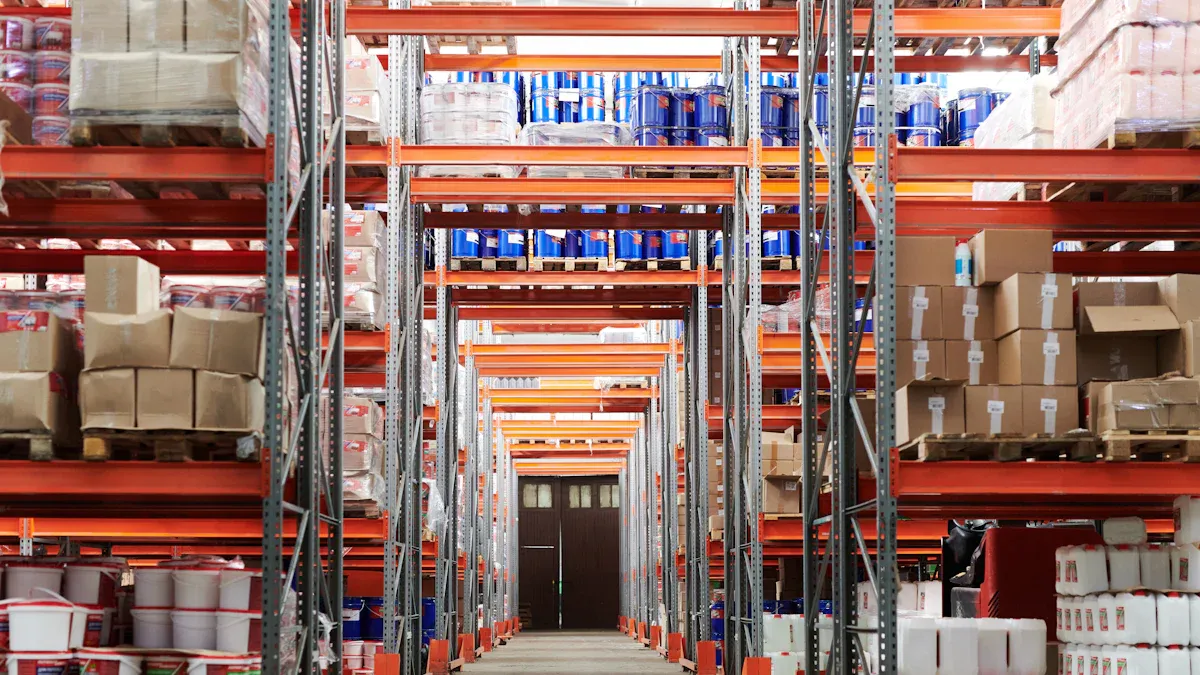

Ensuring Continuity in Fabric Rolls

Continuity in fabric rolls is critical when buying suit fabrics in bulk. I always ensure that my inventory management strategy accounts for demand fluctuations and supplier reliability. Maintaining consistent stock levels prevents disruptions in production and ensures customer satisfaction.

| Factor | Description |

|---|---|

| Safety Stock | Ensures availability during demand variability and lead time. |

| Demand Patterns | Seasonal fluctuations affect reorder points, necessitating adjustments based on historical data. |

| Supplier Reliability | Consistent suppliers allow for closer alignment of reorder points to safety stock levels. |

| Service Level Goals | Desired service levels dictate how reorder points are set to meet customer expectations. |

By collaborating with reliable suppliers and analyzing demand patterns, I can maintain a steady supply of fabric rolls. This strategy helps me avoid delays and ensures that my customers receive high-quality products on time.

Avoiding Overstocking and Waste

Overstocking can lead to significant financial losses, so I always strive to maintain optimal inventory levels. Excess fabric not only ties up capital but also increases storage costs and the risk of obsolescence. To avoid these issues, I carefully monitor inventory turnover and adjust my purchasing strategy accordingly.

| Evidence Type | Description |

|---|---|

| Capital Preservation vs. Opportunity Cost | Overstocking ties up capital in unsold goods, leading to potential profit erosion through discounting. |

| Storage and Handling Costs | Excess inventory incurs higher storage costs, impacting overall profitability. |

| Inventory Obsolescence | Overstocking can lead to unsold items becoming obsolete, affecting sales and revenue. |

| Customer Satisfaction and Loyalty | Maintaining optimal stock levels is crucial for customer retention and satisfaction. |

| Cash Flow Implications | Overstocking can significantly tie up cash, leading to potential cash flow issues for the business. |

By balancing stock levels and avoiding over-purchasing, I can reduce waste and improve my business’s financial health.

Budgeting for Bulk Purchases

Budgeting is a crucial part of planning any bulk purchase. I always allocate funds based on my projected needs and market trends. This ensures that I can secure high-quality fabrics without exceeding my financial limits. I also account for potential hidden costs, such as shipping fees or currency fluctuations, to avoid surprises.

To stay within budget, I negotiate terms with suppliers and explore bulk discounts. This approach allows me to maximize value while maintaining quality. By carefully managing my budget, I can make strategic investments that support long-term growth.

Choosing Reliable Suppliers for Buying Suit Fabrics

Researching TR Suiting Fabric Wholesalers

Finding the right supplier starts with thorough research. I always look for wholesalers specializing in TR suiting fabric. Their expertise ensures access to high-quality materials. I check their reputation by reading reviews and testimonials from other buyers. A supplier with a strong track record often delivers consistent results. I also verify their certifications and compliance with industry standards. This step helps me avoid unreliable sources and ensures I work with professionals.

Requesting Samples for Quality Testing

Before committing to a bulk purchase, I request fabric samples. This allows me to test the material’s quality firsthand. I examine the texture, weight, and color consistency of the samples. If the fabric meets my expectations, I proceed with confidence. Samples also help me compare multiple suppliers. This process ensures I select the best option for my needs. It’s a small investment that prevents costly mistakes later.

Understanding Dye Lot Variations

Dye lot variations can cause significant issues when buying suit fabrics in bulk. I always discuss this with suppliers upfront. Even slight differences in dye lots can lead to mismatched colors in the final product. To avoid this, I request fabrics from the same dye lot whenever possible. If that’s not feasible, I ensure the supplier provides detailed information about potential variations. This helps me plan accordingly and maintain consistency.

Negotiating Terms and Delivery Schedules

Negotiating terms is a critical part of working with suppliers. I focus on securing favorable payment terms and delivery schedules. Clear communication ensures both parties understand expectations. I also discuss lead times and shipping costs to avoid surprises. Building a strong relationship with the supplier often leads to better deals and reliable service. This step ensures a smooth process from order placement to delivery.

Common Mistakes to Avoid When Buying Suit FabricsSkipping Quality Checks

Neglecting quality checks is one of the most common mistakes I’ve seen buyers make. When purchasing in bulk, even minor defects can multiply into significant losses. I always inspect the fabric for issues like uneven weaving, loose threads, or inconsistent dyeing. Using tools like spectrophotometers or conducting manual inspections ensures the fabric meets my standards.

Tip: Never rely solely on supplier claims. Always verify the quality yourself or hire a professional inspector.

Buying Without a Clear Plan

Purchasing without a defined strategy often leads to overstocking or buying unsuitable materials. I always start by identifying my target market and understanding their preferences. For example, if my customers prefer lightweight fabrics for summer suits, I avoid heavy wool blends. Planning ensures I invest in fabrics that align with demand and avoid unnecessary expenses.

Overlooking Fabric Roll Lengths and Widths

Fabric roll dimensions directly impact production efficiency. I’ve learned to confirm the length and width of rolls before placing an order. Rolls that are too short or narrow can disrupt cutting patterns, leading to fabric wastage. I also ensure the dimensions match my production requirements to avoid delays.

Ignoring Supplier Reviews and References

Choosing a supplier without researching their reputation is a risky move. I always read reviews and request references from other buyers. A reliable supplier consistently delivers quality and meets deadlines. Ignoring this step can result in delays, poor-quality fabrics, or even financial losses.

Note: A quick background check on suppliers can save you from costly mistakes. Always prioritize reliability over price.

Evaluating fabric quality, planning purchases, and selecting reliable suppliers are essential steps when buying suit fabrics in bulk. These practices ensure consistent quality and prevent costly mistakes.

Tip: Always request samples, verify supplier credentials, and align purchases with your specific needs. Taking time to research and plan guarantees a smoother buying process and better results.

By following these steps, I can confidently invest in fabrics that meet my business goals.

FAQWhat is the best fabric for suits when buying in bulk?

I recommend wool for its luxurious feel and breathability. For affordability and durability, polyester-rayon blends are excellent options when buying suit fabrics in bulk.

How can I ensure fabric quality when purchasing in bulk?

Always request samples before committing to a bulk order. Inspect the texture, weight, and color consistency to ensure the fabric meets your quality standards.

What should I prioritize when selecting a supplier?

Focus on reliability, reputation, and certifications. A trustworthy supplier ensures consistent quality and timely delivery, which are crucial for successful bulk purchases.

Media Contact

Company Name: Shaoxing Yun Ai Textile Co.,Ltd

Email: Send Email

Phone: 0086-13656855796

Country: China

Website: https://www.iyunaitextile.com/