Highlights

- Rare earth oxides were produced from Halleck Creek ore using the updated preliminary Pre-Feasibility Study (“PFS”) mineral processing flowsheet1

- A Mixed Rare Earth Oxalate and Mixed Rare Earth Oxide were created from purified leachate solution using the material from the impurity removal testing2

- This is the most significant technical milestone achieved for the Project to date

DENVER, Dec. 16, 2025 (GLOBE NEWSWIRE) -- American Rare Earths (ASX: ARR | OTCQX: ARRNF | ADR: AMRRY) (“ARR” or the “Company”) has successfully completed another critical stage in its mineral processing program by producing a mixed rare earths oxide (“MREO”) using the updated preliminary PFS mineral processing flowsheet.

MREO from Halleck Creek (“the Project”) was produced using the material – a pregnant leach solution (“PLS”) – from the impurity removal testing campaign3. This was achieved through precipitating a mixed rare earth oxalate and then creating MREO powder (see Figure 1). This major technical milestone confirms that rare earths can be extracted into metallic oxides from Halleck Creek ore using the updated preliminary PFS mineral processing flowsheet currently being finalized for the upcoming PFS. Solvent extraction computer simulation is now underway, using the results of these tests.

SGS in Lakefield, Ontario, Canada created the MREO from the Halleck Creek PLS through a two-step process. The first step consists of precipitating the metals in solution using oxalic acid to create a mixed rare earth oxalate. Oxalic acid is highly selective in precipitating rare earth elements (“REE”) from PLS while other elements stay in solution. SGS performed three precipitation tests using variable oxalic acid addition rates. The second step, called calcining, involved SGS heating the combined mixed rare earth oxalates to 1,000oC to oxidize the material into a MREO. A beneficial effect of calcining is that it oxidizes the cerium, converting it from Ce3+ to Ce4+. Ce4+ is not soluble in the reagent which will be used to dissolve REEs from the MREO for solvent extraction.

Figure 1 – Halleck Creek Mixed Rare Earth Oxalate (left) and Mixed Rare Earth Oxide (right)

Why it matters?

Producing a MREO from Halleck Creek ore, using the updated preliminary PFS mineral processing flowsheet currently being finalized for the upcoming PFS, is the most significant technical milestone achieved for the Project to date.

MREO is the precursor used to produce individually separated rare earth products through solvent extraction, such as Neodymium-Praseodymium (“NdPr”), Terbium (“Tb”), and Dysprosium (“Dy”). In general, producing MREO is the most challenging technical step in manufacturing separated rare earth oxides. By comparison, the subsequent solvent-extraction stage is a well-established, relatively straightforward process.

Next steps in Halleck Creek’s updated preliminary PFS mineral processing flowsheet development include:

- Solvent extraction simulation, using MetSim, is underway using the analytical results of the MREO. The simulated solvent extraction flowsheet will be used to model and define specifications and costs for a solvent extraction refinery, which is typical for a PFS.

- Process optimization using bulk samples continues in parallel with metallurgy. Comminution testing of test pit ore, from the Cowboy State Mine area, is nearing completion at FL Smidth and Loesche. Bulk ground material from the comminution testing is scheduled for reflux classifying concentrator (“RCC”) separation and induced roll magnetic (“IRM”) concentration at Nagrom. Additional, wet high intensity magnetic separation (“WHIMS”) of fines <53µm is scheduled with Eriez.

- Using a mineralized concentrate from the on-going optimization work, complete a single pass-through mineral processing flowsheet to replicate and validate all hydrometallurgical test results completed to date.

Additional technical details

SGS conducted a small bench scale test for uranium removal using a PLS from multiple secondary neutralization tests. The 24-hour test was conducted using Dowex/Ambersep 21K XLT ion exchange resin. The test reduced the uranium content from 1.27ppm to 0.04ppm, effectively removing 97% of the remaining uranium from solution. Between primary and secondary neutralization, and ion exchange 99% of uranium is removed from the REE enriched PLS.

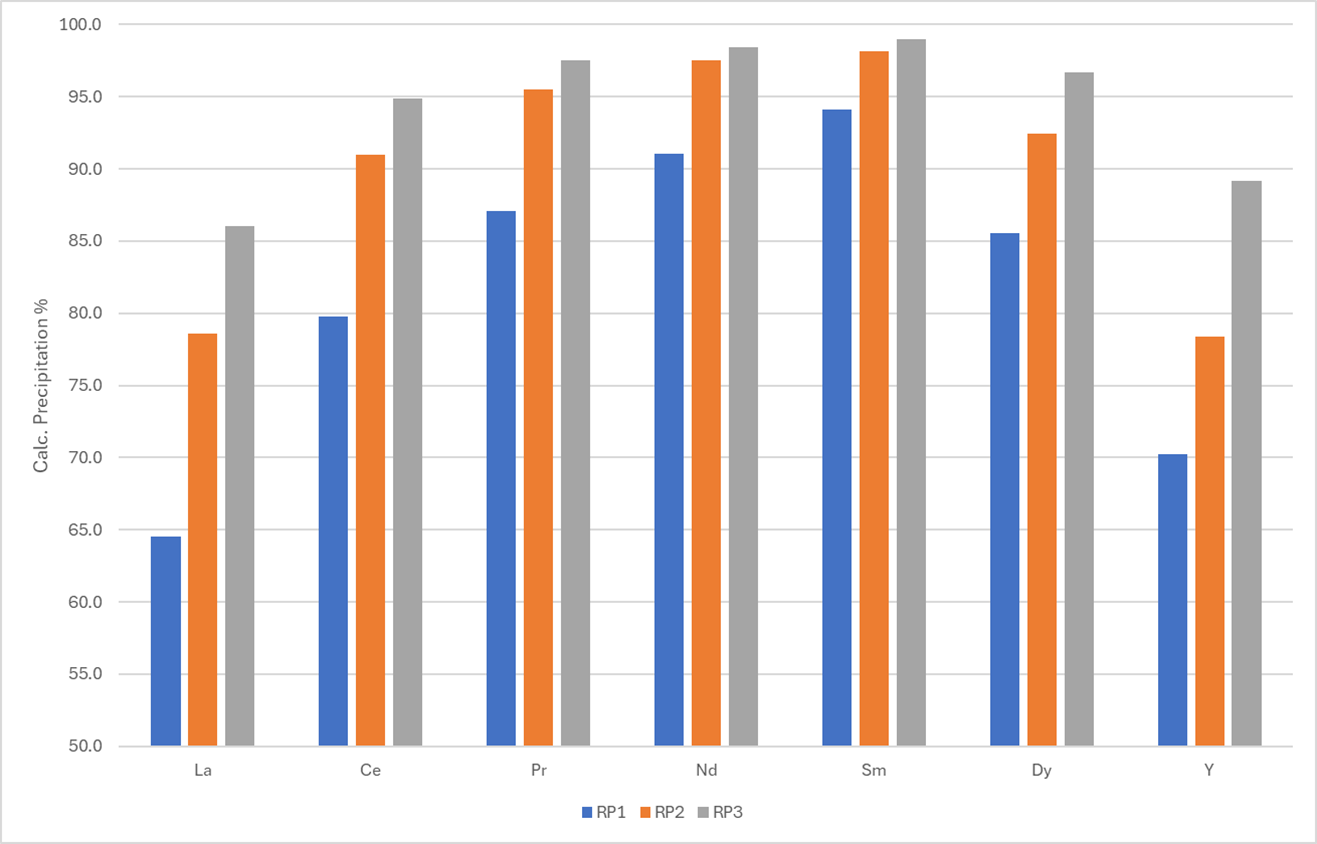

SGS conducted REE precipitation on the PLS using oxalic acid in a 5% solution at 90%, 100% and 110% stoichiometric doses. The average recovery of REE sharply increased between the three tests, showing an average REE recovery of approximately 97% and the average recovery of the magnet REE (Nd, Pr, Sm, Tb and Dy) is approximately 98% under 110% stoichiometric conditions and , see Table 1Table 1, and Figure 2.

Table 1 – REE Precipitation Results from Oxalic Acid Additions

Figure 2 - Calculated Precipitation Percentage of REE

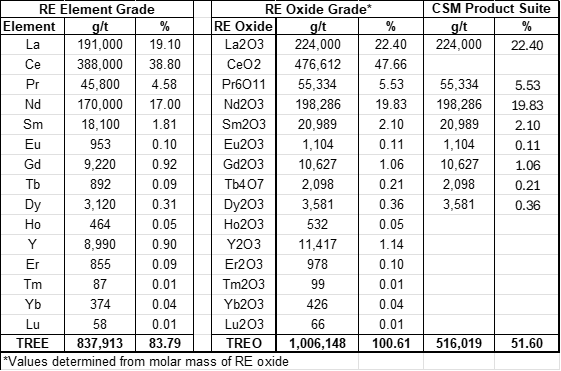

SGS heated the combined mixed rare earth oxalates from sample RP3 at 1,000oC for two hours to oxidize the material into a mixed rare earth oxide, MREO. During the calcining process water and carbon were driven off and the elements were converted to rare earth oxides. Most notably, as stated above, calcining oxidizes cerium, converting it from Ce3+ to Ce4+. The benefit is that Ce4+ is not soluble in the reagent which will be used to dissolve REEs from the MREO for solvent extraction. The assayed results of the MREO are shown in Table 2.

Table 2 – Assay Results of Calcine Test 1

This release was authorized by the board of American Rare Earths.

Investors can follow the Company’s progress at www.americanree.com

Please see here for the full JORC technical report.

About American Rare Earths Limited:

American Rare Earths (ASX: ARR | OTCQX: ARRNF | ADR: AMRRY) is a critical minerals company at the forefront of reshaping the U.S. rare earths industry. Through its wholly owned subsidiary, Wyoming Rare (USA) Inc. (“WRI”), the company is advancing the Halleck Creek Project in Wyoming—a world-class rare earth deposit with the potential to secure America’s critical mineral independence for generations. Located on Wyoming State land, the Cowboy State Mine within Halleck Creek offers cost-efficient open-pit mining methods and benefits from streamlined permitting processes in this mining-friendly state.

With plans for onsite mineral processing and separation facilities, Halleck Creek is strategically positioned to reduce U.S. reliance on imports—predominantly from China—while meeting the growing demand for rare earth elements essential to defense, advanced technologies, and economic security. As exploration progresses, the project’s untapped potential on both State and Federal lands further reinforces its significance as a cornerstone of U.S. supply chain security. In addition to its resource potential, American Rare Earths is committed to environmentally responsible mining practices and continues to collaborate with U.S. Government-supported R&D programs to develop innovative extraction and processing technologies for rare earth elements.

For additional information

Media Contact:

Susan Assadi

sassadi@americanree.com

347 977 7125

Investor Relations US Contact:

Beverly Jedynak

Beverly.jedynak@viriathus.com

312 943 1123

________________________

1 See ASX release dated November 10, 2025

2 See ASX release dated October 13, 2025

3 See ASX release dated October 13, 2025

Figures and tables accompanying this announcement are available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/88a9e78d-cd82-48ce-88a2-3a92c546aa70

https://www.globenewswire.com/NewsRoom/AttachmentNg/f82fafa0-42fe-4331-ab98-8343b2a2a9d4

https://www.globenewswire.com/NewsRoom/AttachmentNg/4778f2da-649d-49db-94de-7efdedd04b0e

https://www.globenewswire.com/NewsRoom/AttachmentNg/11d49aa6-1b2e-4240-a324-2fff29ae79d9