Laser cleaning machine, laser cleaner, rust laser removal, laser cleaningThe laser cleaning machine is advantageous in the cleaning field. It is increasingly popularizing due to its advantages of non-grinding, non-contact, no thermal effects, being applicable to a variety of materials and objects, and high-effective removal of rust, oil, film, oxide, paint, and other pollutants on the surface of the object without damage to the substrate.

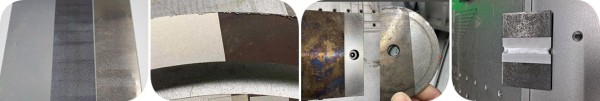

Laser cleaning machine, laser cleaner, rust laser removal, laser cleaningThe laser cleaning machine is advantageous in the cleaning field. It is increasingly popularizing due to its advantages of non-grinding, non-contact, no thermal effects, being applicable to a variety of materials and objects, and high-effective removal of rust, oil, film, oxide, paint, and other pollutants on the surface of the object without damage to the substrate.The laser cleaning machine is advantageous in the cleaning field. It is increasingly popularizing due to its advantages of non-grinding, non-contact, no thermal effects, being applicable to a variety of materials and objects, and high-effective removal of rust, oil, film, oxide, paint, and other pollutants on the surface of the object without damage to the substrate. In some special scenarios, it has even been the only effective cleaning equipment, such as the removal of sub-micron pollution particles, whose adhesion is too strong to be removed by conventional cleaning methods. However, the laser cleaning or rust laser removal machine is able to process these high-viscous particles. In addition, it is safe to clean precision workpieces and small areas with the laser cleaning machine.

Here are five special techniques of laser cleaners:

1. Non-contact with the surface of the object cleaned

Traditional cleaning methods are generally contact-cleaning, that is, the mechanical force being exerted to the surface of the object cleaned, which to some extent damages the surface of the object. In addition, the cleaning medium of those methods attaches to the surface of the object cleaned, which is unable to be removed, resulting in secondary pollution. By comparison, the non-grinding and non-contact of the laser cleaning machine avoid those influences.

2. No damage to the surface of the object

Various pollutants on the surface of diverse materials can be removed by the laser cleaning machine with high cleanliness that traditional cleaning methods fail to achieve. Besides this advantage, it is possible to clean designated areas without damage to the surface of workpieces processed.

3. Precisely positioned

Remote operation through the integration of the laser cleaning machine and robot makes it possible to precisely clean shaped parts, holes, and grooves without contact, which traditional methods are unable to process. This cleaning method ensures the safety of operators, especially in some dangerous processing scenarios.

4. No pollution

Chemical cleansers are not required by the use of the laser cleaning machine, thus no waste liquid being generated. Moreover, pollutant particles and gases generated can be readily processed by a portable extractor fan for waste collection and purification to avoid environmental pollution.

5. Low operating costs

The Laser cleaning system can be used stably for a long-term period. It is equipped with the pulsed laser, whose service life is very long. In addition, no consumables are generated during the processing. On top of these, it is approximately maintenance-free because only regular cleaning or replacement of the lens is required.

Laser cleaning machine has now been widely used in industry, construction, heritage conservation, medicine, and many other fields due to its strengths. In the industrial field, it can be used in the automatic production line and is indispensable for various processes in industrial production, such as welding seam treatment before and after welding, local pollutant treatment before painting, oxide cleaning in the production of highly reactive metals, etc.

Media Contact

Company Name: LASERCHINA

Contact Person: Kevin

Email: Send Email

Phone: 86-10-64426993

Address:#22 Building, #13 Mintai Road Shunyi District

City: Beijing,101300

Country: China

Website: https://www.laserchina.com/