Pipe cutting machines are essential tools in industries ranging from construction and oil & gas to automotive and aerospace manufacturing. The choice of machine type and drive system directly affects cutting speed, precision, and cost efficiency. At SLS Manufacturing, we specialize in pipe processing equipment and understand that whether you need a manual pipe cutting machine for small jobs or a CNC pipe profile cutting machine for high-precision production, selecting the right drive technology is critical.

This article compares the three main drive systems—worm gear, all-gear, and cold saw—while integrating the different machine categories, cutting methods, materials, and industry applications.

1.Worm Gear Drive: High Reduction, Compact & Quiet

How It Works

A worm gear drive in a pipe cutting system uses a worm (screw-like shaft) meshing with a worm wheel (special helical gear) to achieve significant torque reduction, converting motor speed into cutting force. This transmission method is widely applied in manual pipe cutting machines, manual pipe cold cutting machines, and certain electric pipe cutter machines where controlled, low-speed cutting is required.

Key Features

1. High Reduction Ratio (5:1–100:1) – Ideal for low-speed, high-torque cuts in applications such as steel pipe cutting machines or stainless steel pipe cutting machines.

2. Compact Design – Fits small pipe cutting machines and space-limited setups, making it suitable for mobile or field-based pipeline cold cutting machines.

3. Self-Locking Option – Prevents blade backlash for safety, which is valuable when operating pipe cold cutting machines or pipe cutting and beveling machines in on-site construction projects.

4. Lower Efficiency (50–90%) – Requires good lubrication to maintain performance, especially in heavy-duty hydraulic pipe cutting machines.

5. Quiet Operation – Suitable for noise-sensitive environments like indoor workshops, fabrication facilities, and aluminium pipe cutting machine operations.

Best For

General-purpose cutting tasks such as carbon steel, stainless steel pipe cutting, and iron pipe cutting machines used in construction, machining, and maintenance work. Worm gear drives are particularly effective in cold cutting pipe machines where precision and safety outweigh speed.

SLS Solution

SLS Manufacturing offers robust alloy worm gear cutters for reliable, cost-effective performance. Our worm gear systems are compatible with various pipe cutting configurations—from manual hand pipe cutter machines to CNC pipe cutting machines—ensuring long service life and consistent cutting quality for both industrial fabrication and field applications.

2. All-Gear Drive: High Efficiency & Heavy-Duty Performance

How It Works

An all-gear drive system in a pipe cutting machine uses multi-stage gears—such as spur or planetary gears—for power transmission via rolling friction. This design is common in automatic pipe cutting machines, fully automatic pipe cutting machines, and CNC pipe cutting machines, where high efficiency and torque consistency are critical for production lines. The gear train provides stable cutting performance even for large diameter pipe cutting equipment and pipeline beveling machines.

Key Features

1. High Efficiency (95–98%+) – Minimal energy loss makes this ideal for high-output automatic tube cutting machines and CNC tube cutting machines used in metal fabrication plants.

2. Heavy Load Capacity – Perfect for handling thick-walled pipes with steel pipe cutting machines, stainless steel tube cutting machines, or iron pipe cutting machines in oil & gas projects.

3. Long Lifespan – Precision-engineered gears, when maintained properly, extend the operational life of heavy-duty pipe cutting and beveling machines and pipeline cold cutting machines.

4. More Complex Structure – Requires more space compared to worm gear designs, making it more suitable for stationary cold cutting machines or pipe profile cutting machines in factory setups.

5. Moderate Noise – Gear meshing may cause vibration, but in industrial environments such as metal tube cutting machines or aluminium profile cutting machines, this is generally acceptable.

Best For

Demanding applications that require cutting thick-wall materials such as oil and gas pipelines, offshore structural tubes, and heavy industrial piping. Commonly paired with circular saw pipe cutting machines and pipe shearing machines for mass production of components.

SLS Solution

SLS Manufacturing supplies precision-hardened gearboxes for continuous heavy cutting. Our all-gear systems are integrated into CNC pipe profile cutting machines, pipe cold cutting and beveling machines, and high-capacity cold saw machines, ensuring maximum throughput and consistent edge quality in high-demand operations.

3. Cold Saw Drive: High-Speed Precision Cutting

How It Works

A cold saw drive system uses carbide-tipped blades running at ultra-high RPMs (1,000s–10,000+) to deliver clean, burr-free “cold cuts” without generating heat that could distort the material. This technology is widely used in cold saw machines, circular saw machines, and pipe saw cutting machines for industries requiring exceptional accuracy. It is also applied in aluminum cutting machines, aluminum profile cutting machines, and aluminum saw cutting machines where heat-sensitive materials must be processed without damage.

Key Features

1. Ultra-High Speed (100+ m/min blade speed) – Ideal for high-precision work with stainless steel tube cutting machines, metal tube cutting machines, and copper pipe cutting machines in aerospace, automotive, and fabrication industries.

2. Drive Types:

Belt Drive (Most Common) – Absorbs vibration, making it suitable for automatic pipe cutting machines and automatic tube cutting machines where cut stability matters.

Direct Drive (Premium) – Delivers maximum efficiency and micron-level accuracy, often found in CNC pipe cutting machines, CNC tube cutting machines, and CNC pipe profile cutting machines for complex geometry cuts.

Gear Drive (Rare) – Less ideal for ultra-high-speed stability, but still used in certain pipe profile cutting machines and circular saw cutting machines where robust torque is required. Superior Cut Quality – Produces smooth edges without heat distortion, which is critical for pipe cold cutting machines and pipe profile machines in precision manufacturing.

Superior Cut Quality – Produces smooth edges without heat distortion, which is critical for pipe cold cutting machines and pipe profile machines in precision manufacturing.

Best For

Precision applications such as automotive exhaust systems, aerospace tubing, and high-spec structural components. Cold saw drives excel in cutting stainless steel, aluminum, and specialty alloys where weld-ready edges are required.

SLS Solution: SLS Manufacturing integrates German-engineered spindle systems with servo feed control for micron-level precision. Our cold saw solutions are available across fully automatic pipe cutting machines, cold cutting pipe machines, and pipe profile cutting machines, ensuring repeatable accuracy and minimal post-processing for both small-batch and mass-production environments.

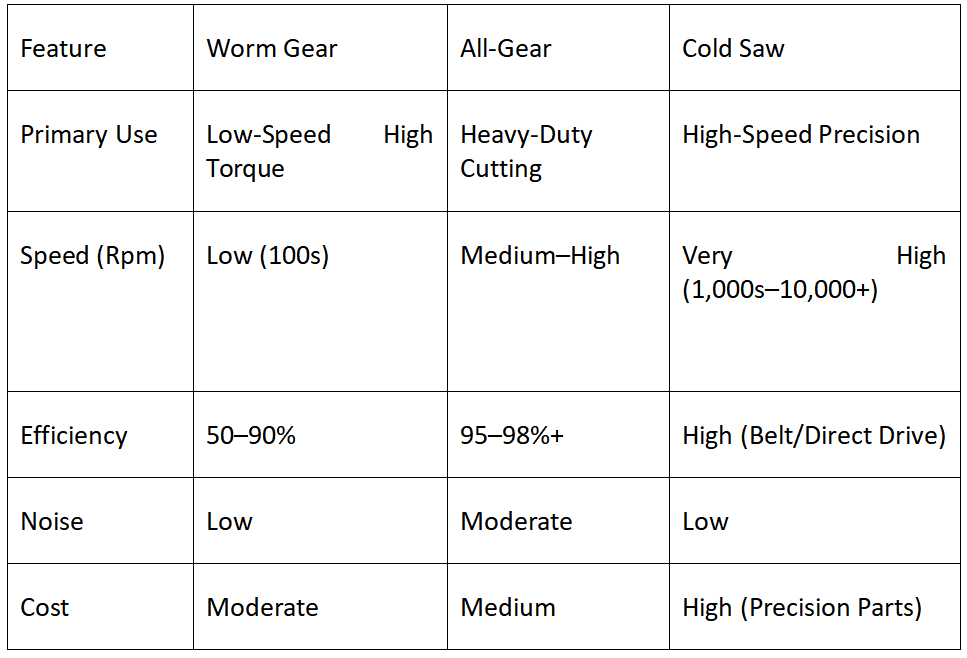

Comparison Summary

SLS Expert Recommendations

Need Compact, Torque-Heavy Cutting? → SLS Worm Gear Cutters

Prioritize Heavy-Duty Efficiency? → SLS All-Gear Cutters

Require Flawless Precision? → SLS Cold Saws (German Tech)

Choose SLS Machinery For Tailored Pipe-Cutting Solutions!

SLS – Your Professional Pipe Processing Partner!

Call: 18100150701

Email: Info@slsmachinery.Com

Website: www.slsmachinery.Com