Gold Resource Corporation (NYSE American: GORO) (the “Company”, “we”, “our” or “GRC”) is pleased to announce the results of a SK1300 compliant Technical Report Summary for an Initial Assessment (“IA” or the “Technical Report”) which comprises an updated Mineral Resource Estimate (“MRE”) and a financial analysis for the Company’s 100% owned Back Forty Project (“Back Forty” or the “Project”), located in the Upper Peninsula of Michigan.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20231026557009/en/

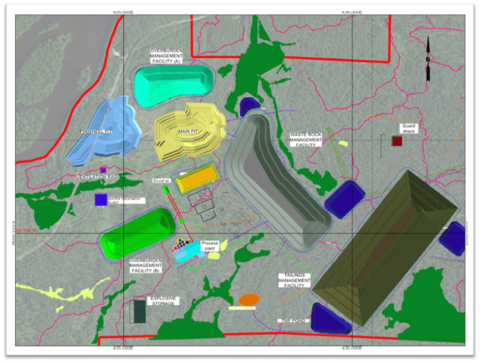

Figure 1: Proposed Back Forty Project Infrastructure Layout (Graphic: Business Wire)

Allen Palmiere, the Company’s CEO stated: “We are very happy with the results of the study. It confirms our belief that the Back Forty Project represents an opportunity to create substantial value for our shareholders. This study is the result of veery strong technical work and represents a compete revision to the mine plan, process flow, project footprint and the elimination of any wetlands impact. It has been designed to minimize the environmental impact by reducing the footprint and adopting dry-stack tailings management thus eliminating the need for a tailings dam. We are very pleased with the results and are looking forward to advancing the project.”

The IA integrates the work done by InnovExplo Inc. (“InnovExplo”), Foth Infrastructure & Environment (“Foth”), and GRC since the 2020 NI43-101 Preliminary Economic Assessment (“PEA”) to improve the Project while at the same time reducing its environmental impact. The results suggest a very robust Project with a moderate capital investment and a 9-year mine life during which 504 koz of gold, 6,150 koz of silver, 61.6 Mlbs of copper and 778 Mlbs of zinc would be produced.

The Project consists in two open pit mines, an underground mine, a nominal 2,500 metric tonnes per day (“tpd”) processing plant and the supporting infrastructures (Figure 1). A 21-month construction period would be followed by open pit mining in the Pinwheel Pit and then in the Main Pit for the first 3 years. Development for the underground mine would start in Year 2 from inside the Main Pit to support the processing plant starting in Year 4.

STUDY HIGHLIGHTS:

- $214.4 million after-tax net present value at a 6% discount rate (“NPV6”) (pre-tax $291.5 million) at a base case metal prices of $1,800 per ounce (“/oz”) for gold, $23.30/oz for silver, $3.90 per pound (“/lb”) for copper, and $1.25/lb for zinc;

- 25.7% after-tax internal rate of return (“IRR”);

- $25.8 million average annual after-tax free cash flow (“FCF”);

- $361.2 million cumulative after-tax life-of-mine (“LOM”) FCF;

- 56,000 ounces (“oz”) of gold, 683,300 oz of silver, 6.8 Mlbs of copper, and 86.4 Mlbs of zinc LOM average annual production

- 504 koz of gold, 6,150 koz of silver, 61.6 Mlbs of copper and 778 Mlbs of zinc LOM total cumulative metal production;

- 2.37 grams per tonne (“g/t”) gold, 26.2 g/t silver, 0.39% copper, and 4.29% zinc for $210 per tonne (“$/t”) net smelter return (“NSR”) average LOM diluted head grade;

- Average overall LOM recovery rates 77.8% for gold, 86.8% for silver, 86.4% for copper, and 95.7% for zinc;

- 84.81 $/t milled LOM total unit operating costs;

- $325.1 million initial capital expenditures (including $28.9 million in contingency costs);

- $102.8 million sustaining capital expenditures (including $8.7 million in contingency costs).

STUDY DETAILS

The Back Forty Project is an advanced stage polymetallic exploration project fully owned by GRC located in the Upper Peninsula of Michigan. The IA was prepared and compiled by GRC with support by independent consulting firms InnovExplo and Foth.

ECONOMIC ANALYSIS

The Company used a base case where material from the inferred resource category was included in the mine plan, and an alternative case without, to highlight the sensitivity of the Project to the resource categories, the high proportion of indicated material and the possible upside of the actual case. The base case has 2.5% of the mill feed from the Inferred category. The metal price assumptions are based on the median of the consensus prices from analysts collected by GRC. These prices are $1,800/oz Au, $23.30/oz Ag, $3.90/lb Cu, and $1.25/lb Zn. Based on these assumptions, the Project generates an after-tax NPV6 of $214 million and an after-tax IRR of 25.7% on an unlevered basis when Inferred resources are included in the mine plan. The case without Inferred resources shows an after-tax NPV6 of $194 million and an after-tax IRR of 24.5% under the same assumptions. The economics of the Project are most sensitive to gold and zinc prices, followed by operating costs and capital costs.

Table 1: Back Forty Project IA Summary Results |

||||

Metric |

Unit |

Base Case with Inferred |

Base Case Indicated only |

|

Total Process Plant Feed |

Mt |

8.77 |

8.55 |

|

Grade |

Au |

g/t |

2.37 |

2.35 |

Ag |

g/t |

26.2 |

25.8 |

|

Cu |

% |

0.39 |

0.38 |

|

Zn |

% |

4.29 |

4.34 |

|

NSR |

$/t |

210.38 |

209.57 |

|

Payable metal |

Au |

koz |

487.6 |

472.8 |

Ag |

koz |

4,800.9 |

4,605.9 |

|

Cu |

Mlbs |

59.1 |

56.5 |

|

Zn |

Mlbs |

658.0 |

645.7 |

|

Life of Mine (“LOM”) |

Years |

9.0 |

9.0 |

|

Metal Prices |

Au |

$/oz |

1,800 |

1,800 |

Ag |

$/oz |

23.30 |

23.30 |

|

Cu |

$/lb |

3.90 |

3.90 |

|

Zn |

$/lb |

1.25 |

1.25 |

|

Gross Revenue |

$M |

2,042.5 |

1,985.9 |

|

Charges |

$M |

180.0 |

176.1 |

|

Penalties |

$M |

17.4 |

18.0 |

|

Net Revenue |

$M |

1,845.1 |

1,791.8 |

|

Stream |

Au |

$M |

113.7 |

110.2 |

Ag |

$M |

78.8 |

75.6 |

|

Royalties |

$M |

24.2 |

24.1 |

|

Taxes |

$M |

106.7 |

103.6 |

|

OPEX |

Total |

$M |

743.8 |

732.6 |

per tonne |

$/t |

84.81 |

85.69 |

|

CAPEX |

Initial |

$M |

325.1 |

325.4 |

Sustaining |

$M |

102.8 |

103.8 |

|

Cashflow Pre-Tax |

$M |

471.2 |

434.6 |

|

Cashflow Post-Tax |

$M |

361.2 |

331.0 |

|

Discounted Cashflow Post-Tax @ 6% |

$M |

214.4 |

194.2 |

|

Post-Tax internal rate of return |

% |

25.7 |

24.5 |

|

Post-Tax Payback |

Years |

2.4 |

2.5 |

|

|

-50% |

-40% |

-30% |

-20% |

-10% |

0% |

10% |

20% |

30% |

40% |

50% |

Au Price |

-29.6 |

23.3 |

75.3 |

122.3 |

168.6 |

214.4 |

259.4 |

303.7 |

347.1 |

390.5 |

433.7 |

Ag Price |

210.4 |

211.2 |

212.0 |

212.8 |

213.6 |

214.4 |

215.3 |

216.0 |

216.8 |

217.7 |

218.5 |

Cu Price |

139.1 |

154.1 |

169.3 |

184.3 |

199.4 |

214.4 |

229.2 |

243.8 |

258.4 |

272.9 |

287.3 |

Zn Price |

-26.2 |

26.1 |

76.4 |

123.0 |

169.2 |

214.4 |

259.0 |

302.6 |

345.8 |

388.8 |

431.4 |

OPEX |

439.0 |

395.2 |

351.4 |

306.8 |

261.4 |

214.4 |

165.6 |

115.6 |

65.1 |

9.2 |

-47.0 |

CAPEX |

408.0 |

369.3 |

330.6 |

291.9 |

253.2 |

214.4 |

175.7 |

137.0 |

98.3 |

59.6 |

20.9 |

|

-50% |

-40% |

-30% |

-20% |

-10% |

0% |

10% |

20% |

30% |

40% |

50% |

Au Price |

3.1% |

8.2% |

13.0% |

17.3% |

21.5% |

25.7% |

29.7% |

33.6% |

37.4% |

41.1% |

44.7% |

Ag Price |

25.3% |

25.4% |

25.5% |

25.5% |

25.6% |

25.7% |

25.8% |

25.8% |

25.9% |

26.0% |

26.1% |

Cu Price |

18.0% |

19.5% |

21.0% |

22.5% |

24.1% |

25.7% |

27.3% |

28.9% |

30.5% |

32.2% |

33.9% |

Zn Price |

1.7% |

9.4% |

14.8% |

19.0% |

22.6% |

25.7% |

28.5% |

31.0% |

33.4% |

35.5% |

37.5% |

OPEX |

41.8% |

38.8% |

35.8% |

32.7% |

29.3% |

25.7% |

21.7% |

17.5% |

12.8% |

7.0% |

0.0% |

CAPEX |

89.9% |

65.9% |

50.6% |

39.9% |

31.9% |

25.7% |

20.7% |

16.5% |

13.0% |

9.9% |

7.3% |

MINERAL RESOURCE ESTIMATE

The IA includes an updated MRE done by InnovExplo. No additional drilling has occurred on site since 2019, but the geological interpretation, interpolation parameters and NSR calculations were updated. This represents an increase of 17% in the total value in the block model (NSR x tonnes) compared to the previous MRE. However, deductions for the gold and silver streams, along with the royalties, were included in the NSR calculations against the cut-off grade (“CoG”). These deductions were not part of the previous MRE. When the deductions are included, the total value in the block model is 4% less than the previous MRE. The underground part of the MRE was confined using a Stope Optimizer software, which is more restrictive than the method used in the previous MRE. The CoG for open pit and underground were updated to reflect costs closer to the proposed mining methods. In total, the Measured and Indicated resource reduced by 21% while the Inferred resource is within 1% of the previous MRE. The effective date of the MRE is September 30th, 2023.

Table 2: Back Forty Project Mineral Resource Statement - September 30th, 2023 |

|||||||||||

Area (Mining Method) |

Classification |

NSR cut-off ($/t) |

Tonnes (000s) |

Au (g/t) |

Au (Moz) |

Ag (g/t) |

Ag (Moz) |

Zn (%) |

Zn (Mbs) |

Cu (%) |

Cu (lbs) |

Open pit |

Indicated |

33 |

9,360 |

2.41 |

725 |

28.06 |

8,444 |

3.74 |

772 |

0.36 |

74 |

Inferred |

33 |

566 |

2.70 |

49 |

48.84 |

889 |

1.31 |

16 |

0.35 |

4 |

|

UG long hole |

Indicated |

73 |

5,137 |

1.86 |

306 |

24.05 |

3,972 |

2.65 |

300 |

0.41 |

47 |

Inferred |

73 |

627 |

2.00 |

40 |

26.10 |

526 |

2.89 |

40 |

0.37 |

5 |

|

Total Indicated |

14,497 |

2.21 |

1,032 |

26.64 |

12,416 |

3.35 |

1,072 |

0.38 |

121 |

||

Total Inferred |

1,193 |

2.33 |

89 |

36.89 |

1,415 |

2.14 |

56 |

0.36 |

9 |

||

Notes to accompany the Mineral Resource Estimate:

- The independent and qualified persons for the mineral resource estimate, as defined by S-K 1300, are Marina Iund, P.Geo., Carl Pelletier, P.Geo. and Simon Boudreau, P.Eng. all from InnovExplo Inc. The effective date is September 30th, 2023.

- These mineral resources are not mineral reserves, as they do not have demonstrated economic viability. The mineral resource estimate is reported in accordance with the S-K 1300 Regulations and Definition Standards.

- The results are presented undiluted and are considered to have reasonable prospects of economic viability.

- The estimate encompasses a gold, silver, zinc and copper deposit subdivided into 53 individual zones using the grade of the adjacent material when assayed or a value of zero when not assayed. Fifty-three 10 m buffers around each zone were also created.

- High-grade capping supported by statistical analysis was done on raw assay data before compositing and is established on a per-zone basis varying from 40 to 75 g/t Au; 350 to 1100 g/t Ag; 0.6 to 12% Cu and none to 14% Zn.

- The estimate was completed using sub-block models in GEOVIA Surpac 2022.

- Grade interpolation was performed on 1.5 m composites with the ID3 method for Au and Ag and the ID2 for Zn and Cu.

- The density was interpolated with the ID2 method for Type 1 (rich massive sulfide mineralized zones), Type 2 (stockwork stringer and peripheral sulfide mineralized zones) and Type 3 (precious metal-rich, low sulfide mineralized zones). A value of 3.05 g/cm3 was assigned to Type 4 (gossan mineralized zones). A value of 2.7 g/cm3 was assigned to the surrounding waste and to the cross-cutting mafic dykes. A value of 2.00 g/cm3 was assigned to the overburden and the cross-cutting sandstone unit.

- The mineral resource estimate is classified as Indicated and Inferred. For Type 3 zones, the Indicated mineral resource category is defined for blocks estimated in the first pass, with a closest distance of 45 m and where there is reasonable geological and grade continuity. The Inferred category is defined for blocks estimated in the first and/or second pass, with a closest distance of 90 m and where there is reasonable geological and grade continuity. For Types 1,2 and 4 zones, the Indicated mineral resource category is defined for blocks estimated in the first pass, with a closest distance of 55 m and where there is reasonable geological and grade continuity. The Inferred category is defined for blocks estimated in the first and/or second pass, with a closest distance of 110 m and where there is reasonable geological and grade continuity.

- The mineral resource estimate is locally pit-constrained with a bedrock slope angle from 31 to 49° and an overburden slope angle of 30°. It is reported at a rounded NSR cut-off of $33/t (in pit) and $73/t (underground). The NSR cut-off was calculated using the following parameters: Total processing cost = $28.00/t; Ore premium mining cost = none to $40.00/t; Administration & General = $5.00/t; gold price = $1,800.00/oz; silver price = $23.30/oz; copper price = $3.90/lb and zinc price = $1.25/lb. The cut-off grades should be re-evaluated in light of future prevailing market conditions (metal prices, exchange rates, mining costs etc.).

- The number of metric tonnes was rounded to the nearest thousand, and any discrepancies in the totals are due to rounding effects. The metal contents are presented in troy ounces (tonnes x grade / 31.10348).

- The authors are not aware of any known environmental, permitting, legal, title-related, taxation, socio-political, or marketing issues, or any other relevant issue not reported in the Technical Report, that could materially affect the MRE.

CAPITAL COSTS

The total initial capital cost for the construction of the Back Forty Project is estimated at $325.1M. The sustaining capital, which includes the capital required to bring the underground mine into production starting in 2028, is estimated at $102.8M. In both cases, contingencies and indirect costs are included in the estimations.

Table 3: Back Forty Project Capital Costs Summary |

|||

Cost Area |

Initial capital cost ($M) |

Sustaining capital cost ($M) |

Total cost ($M) |

Mobile equipment |

5.8 |

24.3 |

30.1 |

Open pit mine |

1.4 |

1.7 |

3.1 |

Underground mine |

- |

50.6 |

50.6 |

Capitalized OPEX |

17.9 |

7.3 |

25.1 |

Electrical and communications |

8.1 |

- |

8.1 |

Surface infrastructures |

26.8 |

4.9 |

31.7 |

Process plant |

131.1 |

5.4 |

136.5 |

Rock and tailings management |

27.9 |

- |

27.9 |

Water treatment plant |

21.8 |

- |

21.8 |

Construction indirects |

22.0 |

- |

22.0 |

Owner’s costs |

33.5 |

- |

33.5 |

Contingency |

28.9 |

8.7 |

37.6 |

Total |

325.1 |

102.8 |

427.9 |

Site reclamation and closure |

- |

22.6 |

22.6 |

Salvage value |

- |

(7.1) |

(7.1) |

Project total |

325.1 |

118.4 |

443.5 |

OPERATING COSTS

The operating costs estimate includes mining, both open pit and underground, ore processing, concentrate shipping, tailings management, water treatment and general and administration expenses. The average operating costs over the 9-year mine life is estimated to be $84.81/t. The open pit mining operating costs are estimated at $6.04/t mined while the underground mining costs are estimated at $38.04/t mined.

Table 4: Back Forty Project Operating Costs |

||

Cost area |

Total cost ($M) |

Cost per tonne milled |

Overburden Removal and Storage |

5.4 |

0.61 |

Open Pit Mining |

50.4 |

5.75 |

Underground Mining |

194.6 |

22.19 |

Rehandling |

1.0 |

0.12 |

Processing |

256.9 |

29.30 |

Tailings Deposition |

23.7 |

2.70 |

WRMF Reclamation |

4.4 |

0.51 |

General and Administration |

79.6 |

9.07 |

Concentrate Shipping |

153.0 |

17.44 |

Capitalized OPEX |

(25.1) |

(2.87) |

Total |

743.8 |

84.81 |

MINING

The mine plan consists of a combined open pit and underground mining operation at an average 2,600 tpd. Open pit mining will take place from Year 1 to Year 4. Underground development will be initiated in Year 2 and underground production mining will continue to Year 10.

Open pit mining will occur in two distinct areas, the Pinwheel pit and the Main pit. The Pinwheel pit will be mined first and contains material with a higher grade in gold and copper than the average resource. This pit will be mined for 18 months. The Main pit will be started at the end of year 1 to complement the production of the Pinwheel pit. Waste material from the Main pit will be used to backfill the Pinwheel pit once its resources are exhausted.

The development of the underground mine will start at the end of Year 2 with a portal located inside the Main pit. Production from the underground mine will start replacing the open pit one in Year 4. Mining underground is accomplished mostly from long hole open stoping with stopes averaging 24,000 t.

PROCESSING

The processing facility will be used to process at a nominal rate of 2,500 tpd of mineralized material and up to 2,800 based on feed material characteristics over the LOM. The flowsheet consists of a three-stage crushing followed by ball mill to a target P80 size of 50 microns. The facility will have two flotation circuits to recover copper and zinc. The copper and zinc circuits will see their respective concentrate filtered to reduce residual moisture content to approximately 10%. Both concentrates will be loaded for shipment to smelters.

Zinc flotation tailings will be leached and dewatered using a press filter. Solids will be washed and dewatered to 15% humidity in the press filter before being sent to dry stack. Filtrate from the press filter will be processed through reverse osmosis membrane for salt rejection and through the SART circuit. Cyanide species from the solution will be converted to NaCN. Precious metals are recovered from solution in zinc precipitation circuit. Precious metal barren solution will be recirculated to leaching and recycled cyanide will be re-introduced. Cyanide destruction will be performed on excess dilute solution from the press filter not processed by SART and released to the collecting pond.

Paste backfill will be installed later during the life of mine when the underground mine will be in operation.

The proposed process will recover zinc and copper concentrates, as well as gold and silver in the form of doré bars. SART process will also generate copper and zinc concentrate. The copper concentrate flotation will have an estimated average of 14% copper content as well as payable gold and silver; the zinc concentrate flotation will have an estimated average of 51% zinc content.

INFRASTRUCTURES

The Back Forty Project is situated in a location with close proximity to existing infrastructure. There are road networks on either side of the property and a high voltage electrical transmission corridor near the main access county road, providing grid power. Water is collected from different areas within the property at the Contact Water Basin and either re-distributed for use within the facility or treated for discharge.

The project site can be largely divided into five main areas:

- Access from County Road 356 leading to security gates for site entry.

- Facility Storage Areas: Waste Rock Management Facility (“WRMF”), Two Overburden Management Facilities (“OMF”), Ore Storage Facility (“OSF”) and Tailings Management Facility (“TMF”), as well as the associated water collection ponds.

- Central area where the crushing, mill, administration, electrical substation, shop and ancillary facilities are located.

- Contact Water Basin (“CWB”) and Waste Water Treatment Plant (“WWTP”).

- The open pit area is comprised of the two open pits, the underground portal located inside the Main pit and the underground ventilation infrastructures to the southwest of the open pit. To the east of the open pit there is an area designated for ore stockpiling, and adjacent to this is the overburden stockpile

TECHNICAL INFORMATION AND QUALIFIED PERSONS

The IA is prepared by personnel of GRC and independent representatives of InnovExplo and Foth, each of whom is a "qualified person" (within the meaning of Regulation S-K Subpart 229.1300 Disclosure by Registrants Engaged in Mining Operations (“SK1300”)) (each, a "QP"). Each of the QPs have reviewed and confirmed that this news release fairly and accurately reflects, in the form and context in which it appears, the information contained in the respective sections of the Back Forty IA for which they are responsible. At the effective date of the IA, the QPs certified that to the best of their information, knowledge and belief, the parts of the IA for which they were responsible, contained all scientific and technical information that was required to be disclosed to make the Back Forty Project IA not misleading. The affiliation and areas of responsibility for each QP involved in preparing the IA are provided below.

InnovExplo QPs

- Carl Pelletier, P.Geo – Mineral Resources Estimate

- Marina Iund, P.Geo – Mineral Resources Estimate

- Eric Kinnan, P. Geo – Data Verification

- Simon Boudreau, P.Eng – Mineral Resources Estimate

Foth QPs

- Andrea K. Martin, P.Eng – Environmental Studies and Permitting

GRC QPs

- Rodrigo Simidu, P.Eng – Underground Mining

- Michael J. Foley, P.Eng – Infrastructures

- Christian Laroche, P.Eng – Metallurgical testing and Process Plant Design

- Patrick Frenette, P.Eng – Open Pit Mining, Capital Costs, Operating Costs, Economic Analysis, Overall study integration.

About GRC:

Gold Resource Corporation is a gold and silver producer with its operations centered on the Don David Gold Mine in Oaxaca, Mexico its Back Forty gold-copper development Project in Michigan, USA. Under the direction of an experienced board and senior leadership team, the Company’s focus is to unlock the significant exploration upside of its mine and surrounding large land package to the benefit of its existing infrastructure. For more information, please visit GRC’s website, located at www.goldresourcecorp.com and read the Company’s Annual Report on Form 10-K for the fiscal year ended December 31, 2022 for an understanding of the risk factors associated with its business.

Forward-Looking Statements:

This press release contains forward-looking statements that involve risks and uncertainties. The statements contained in this press release that are not purely historical are forward-looking statements within the meaning of Section 27A of the Securities Act of 1933, as amended, and Section 21E of the Exchange Act of 1934, as amended. When used in this press release, the words “plan”, “target”, "anticipate," "believe," "estimate," "intend" and "expect" and similar expressions are intended to identify such forward-looking statements. Such forward-looking statements include, without limitation, the statements regarding the potential for additional mineral resources in future mine plans. All forward-looking statements in this press release are based upon information available to Gold Resource Corporation as of the date of this press release, and the Company assumes no obligation to update any such forward-looking statements. Forward looking statements involve a number of risks and uncertainties, and there can be no assurance that such statements will prove to be accurate. Forward-looking statements are subject to risks and uncertainties, including the possibility of lower than anticipated revenue or higher than anticipated costs, volatility in commodity prices, and declines in general economic conditions. Additional risks related to the Company may be found in the periodic and current reports filed with the SEC by the Company, including the Company’s Annual Report on Form 10-K for the year ended December 31, 2022, which are available on the SEC’s website at www.sec.gov.

View source version on businesswire.com: https://www.businesswire.com/news/home/20231026557009/en/

Contacts

Allen Palmiere

Chief Executive Officer

www.goldresourcecorp.com